How Once-Popular Pool Halls Ushered in the Age of Plastic

Courtesy of Usodesita/Flickr

Roman Mars’ podcast 99% Invisible covers design questions large and small, from his fascination with rebar to the history of slot machines to the great Los Angeles Red Car conspiracy. Here at The Eye, we cross-post new episodes and host excerpts from the 99% Invisible blog, which offers complementary visuals for each episode.

This week's edition—about billiards—can be played below. Or keep reading to learn more.

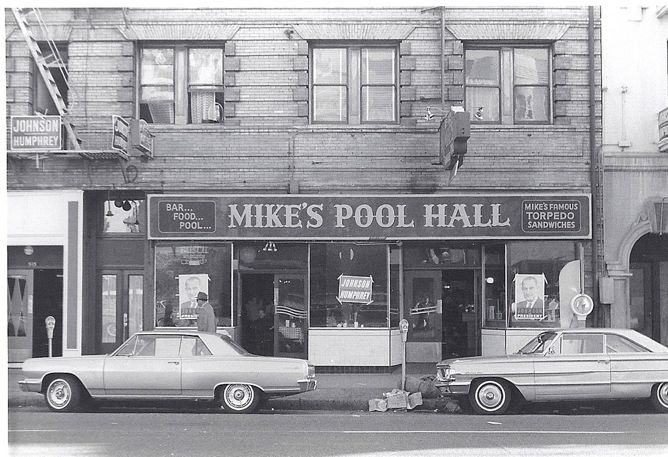

There was an age of billiards, and it has been over for so long that most of us have no idea how huge billiards once was. For many decades, starting in the mid-19th century, billiards was the one of the most popular amusements. A hundred years ago, there were 830 pool halls in the city of Chicago. Today, there are 10.

Billiards is not what it used to be, but we continue to live in a world affected by its former prominence. The growth of billiards led to the development of a material that would come to define the modern world. Without billiards, we might never have discovered plastic.

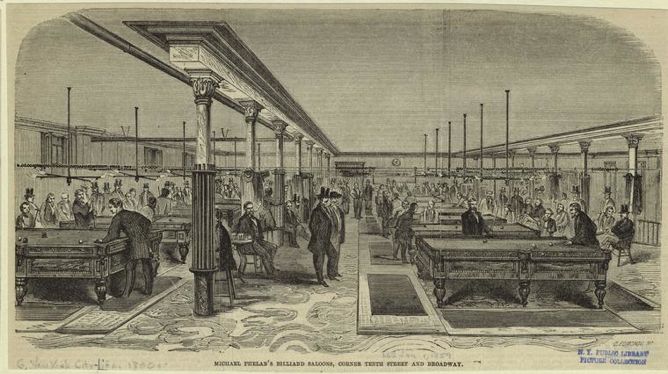

The story starts with a man named Michael Phelan, the father of American billiards. A brilliant player, he also promoted the sport, arranging the biggest big-money matches. He opened huge billiards halls in San Francisco and New York. Phelan believed that to further popularize the game of billiards, he would need to standardize the gear. If tables and balls weren’t the same from one location to another—well, you were basically playing a different game every time you went somewhere new.

Courtesy of the New York Public Library/Wikimedia Commons

So he patented a new kind of billiard cushion and used the proceeds from selling it—plus what he had won playing billiards and writing books on billiards—and became the first big manufacturer of billiards tables and equipment. But standardizing the billiard ball was no easy task. The ball has to rebound properly and be of uniform density. At the time, there was really only one material that would do: ivory.

Ivory was not cheap. Going to Africa, shooting elephants, processing their tusks, and shipping them across an ocean was dangerous and expensive (not to mention horrible). So people in the billiards industry started looking for substitutes. They tried a variety of materials, like wood and iron, but they didn’t perform nearly as well. Ivory balls had just the right weight, the most even roll, the best rebound. Nothing was as good, and only the best-grade ivory would do. (In fact, records from the ivory trade sometimes refer to the top grade as “billiard ball ivory.”) Unlike the ivory on piano keys, which were just a veneer to cover wood, billiard balls had to be made of 100 percent solid ivory. The average number of billiard balls that could be obtained from a single tusk was three.

You can watch ivory being turned into a billiard in the Dutch-language archival video below:

The cost of ivory billiard balls was a problem for Phelan, who was trying to grow his company. He and his colleagues were acutely aware that they needed to find another material. Phelan took out an ad in the paper, offering $10,000 ($3 million in today’s dollars) to anyone who could come up with a suitable replacement for ivory.

A tinkerer named John Wesley Hyatt found the ad. Hyatt was a printer, not a scientist. But in his work he used a number of different chemicals, including nitrated cellulose. Nitrated cellulose was used by printers to protect their hands and is still sold today as liquid bandages. Hyatt found that the material turned out to have very interesting properties. In particular, when dissolved, it created a kind of syrupy liquid. He tried making a film out of it and then putting it through a press. In doing this, he created the first plastic. He called it “celluloid.”

But Hyatt did not win Phelan’s prize. Celluloid turned out be useful for a number of things, but it didn’t give the right bounce for billiard balls. Hyatt tried to make a go of it anyway, setting up his own billiard ball company, making balls with a thin veneer of celluloid over a layer of plaster on the inside. But they were considered very inferior billiard balls.

Courtesy of Gary Stevens/Flickr

So Hyatt went into business with his brother Isaiah, setting up companies to try to find new uses for the material. Eventually they found that the best use for celluloid is imitation ivory. Albeit, not for billiard balls, but for versions of popular ivory luxury goods, such as knife handles, combs, and hand mirrors. And of course, celluloid would eventually be used to make film for movies. Though celluloid had one fatal flaw: It burned easily. Celluloid film caused several disastrous and fatal fires in movie theaters.

Celluloid hadn’t worked for billiard balls, but it did inspire others to make new types of plastics, like a petroleum-based plastic invented in 1907 by Leo Baekeland. He named it Bakelite, after himself. And Bakelite plastic was perfect for billiard balls.

By the 1940s, even top pool tournaments were being played with plastic balls. But by then, pool had passed its peak. It crashed as the Depression began and never regained its former prominence. The age of billiards was over. We have been in the post-billiards age—the age of plastics—ever since.

To learn more, check out the 99% Invisible post or listen to the show.