3-D printers have limitations. We can’t get them to do everything we want them to. At least not yet.

But Jim Smith at Grass Roots Engineering wants to go beyond plastic bottle openers. So he printed a kayak that’s watertight and floats.

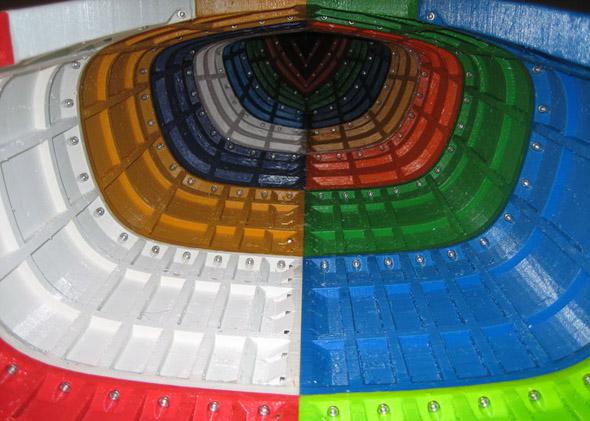

Smith works at the company 3D Systems and builds custom printers at his house in his spare time, so he’s not exactly the average home tinkerer. Still, the kayak is made of ABS plastic, machine screws, brass threaded inserts, and silicone caulk, so the materials are readily available.

It took Smith $500 worth of materials and 42 days of printing to create the 28 parts that he then assembled into the 16-foot-8-inch kayak. He also had to do some modifications on the custom printer he uses at home so there would be room to print the pieces and they wouldn’t crack or bend. Smith writes in a blog post:

This design was initially based on the Siskiwit Bay kayak by Bryan Hansel, but heavily modified for 3D printing. The shape of the kayak was tweaked to optimize performance based on my height and weight. … It features a 6mm thick hull with a built-in, internal rib/support structure to give it strength, yet be lightweight and use less ABS plastic. On the bow and stern of the Kayak I added attach points for cameras, handles and future add-ons.

Kayaks can easily be $1,000, so at $500 Smith’s personalized model is a steal—depending on how it handles and how long it lasts. Printing custom sea vessels may not be for everyone, but it’s nice to see a 3-D printer make something human-sized that’s great looking and actually works.

Photo courtesy of Jim Smith/Grass Roots Engineering.

Photo courtesy of Jim Smith/Grass Roots Engineering.